If you are looking for a dependable 24V output from a car battery, we have the right solution. We’ll show you how to convert a car battery’s 24V current to DC in this article, allowing you to create a wide range of devices and applications. You’ll learn everything you need to know about converting power in our step-by-step instructions and conversion methods. By following these steps, you’ll be able to unlock the full potential of your car battery.

This article will go over how to obtain 24V from a car battery in detail. Step-up voltage converters, voltage divider circuits, series connections of batteries, and power inverters will all be covered during the course. In this article, you will learn how to properly and safely power up your device, whether you are a DIY enthusiast or looking for a reliable source of power.

This course will walk you through the various voltage conversion techniques for your car battery, giving you step-by-step instructions and troubleshooting tips, as well as important safety considerations. You can learn about the world of 24V power generation from a car battery by grabbing your tools.

Understanding Car Batteries

When it comes to understanding car batteries, it’s essential to grasp the basic functioning and voltage specifications that drive these powerhouses of automotive energy. Car batteries play a crucial role in providing the electrical power needed to start the engine, operate various systems, and keep your vehicle running smoothly. So, let’s dive into the intricacies of car batteries and explore their fundamental principles.

At its core, a car battery is a rechargeable device that stores electrical energy in chemical form and converts it into electrical power when needed. It is a vital component of the vehicle’s electrical system, supplying the necessary current to start the engine and power the lights, radio, air conditioning, and other electrical accessories. Without a functioning battery, your car simply wouldn’t be able to operate.

Car batteries typically operate at a nominal voltage of 12 volts, although some vehicles may utilize a higher voltage system, such as 24 volts, for specific applications. This voltage specification is crucial for ensuring compatibility with the electrical components and systems within the vehicle. It is important to note that the voltage provided by the battery remains relatively constant while in use.

To better understand car batteries, let’s take a closer look at their voltage specifications:

Nominal Voltage: The nominal voltage refers to the average voltage that a battery is designed to deliver. In the case of car batteries, the standard nominal voltage is 12 volts. This value indicates the battery’s typical voltage output under normal operating conditions.

Open Circuit Voltage: The open circuit voltage represents the battery’s voltage when it is not connected to any electrical load or charging source. For a fully charged car battery, the open circuit voltage should be around 12.6 to 12.8 volts. However, it is important to note that the open circuit voltage may vary depending on factors such as temperature and the battery’s state of charge.

Cranking Voltage: Cranking voltage, also known as starting voltage, refers to the battery’s voltage output during engine cranking or starting. It is essential for providing the necessary power to turn the engine’s starter motor. A healthy car battery should maintain a cranking voltage above 9.6 volts under load.

Deep Discharge Voltage: Deep discharge voltage represents the minimum voltage level at which a battery should be discharged to avoid potential damage. For car batteries, the deep discharge voltage is typically around 10.5 volts. Discharging a battery below this threshold can lead to reduced performance and may even cause irreversible damage to the battery.

Understanding these voltage specifications is crucial for ensuring optimal battery performance, identifying potential issues, and selecting the right battery for your vehicle. It is worth mentioning that different types of car batteries, such as lead-acid, lithium-ion, or absorbed glass mat (AGM) batteries, may have variations in their voltage characteristics and charging requirements.

Assessing Power Requirements

When it comes to powering devices using a car battery, it is crucial to assess the power requirements of the specific device and consider voltage compatibility and specifications. By understanding these factors, you can ensure that the device receives the necessary power and avoid any potential issues. Let’s delve into the process of assessing power requirements and the importance of voltage compatibility.

Determining Power Requirements:

- Start by identifying the power requirements of the device you intend to power with the car battery. This includes determining the voltage and current specifications.

- Check the device’s user manual or specifications sheet for information on its power requirements. Look for details such as the required voltage, expressed in volts (V), and the current consumption, expressed in amperes (A).

- Consider the device’s power consumption during different operating modes, such as standby, idle, and peak usage. This will help you understand the device’s power needs under various conditions.

Voltage Compatibility and Specifications:

- Once you have determined the device’s power requirements, it is essential to ensure voltage compatibility with the car battery. In most cases, car batteries provide a nominal voltage of 12 volts.

- Check if the device is designed to operate within the voltage range provided by the car battery. Some devices, especially automotive accessories, are specifically designed to be compatible with the 12V output of a car battery.

- In situations where the device requires a different voltage, such as 5V or 24V, you will need to employ voltage conversion methods to match the device’s requirements. This can involve using step-up voltage converters, voltage divider circuits, series connection of batteries, or power inverters to achieve the desired voltage output.

It is important to note that using voltage conversion methods may introduce efficiency losses and potential risks. Therefore, it is recommended to choose the most suitable method based on factors such as power efficiency, voltage stability, and the specific needs of your device.

By assessing the power requirements of the device and ensuring voltage compatibility, you can successfully power your device using a car battery. This opens up possibilities for various applications, such as camping equipment, portable electronic devices, or even running small appliances in off-grid settings.

In conclusion, when considering powering devices from a car battery, it is essential to assess the power requirements and voltage compatibility of the specific device. Determining the device’s power requirements and understanding its voltage specifications will help you select the appropriate voltage conversion method, if needed, and ensure that the device receives the necessary power. By taking these factors into consideration, you can leverage the power of a car battery to conveniently and effectively operate your devices in a variety of settings. So, before connecting your device to a car battery, make sure to assess its power needs and voltage compatibility for a successful power supply experience.

Voltage Conversion Methods

When it comes to converting voltage to match the requirements of specific devices, there are several effective methods that can be employed. Understanding these voltage conversion methods allows you to power devices efficiently and effectively. Let’s explore four commonly used voltage conversion methods: step-up voltage converters, voltage divider circuits, series connection of batteries, and power inverters.

Step-up Voltage Converters (DC-DC Converters):

- Step-up voltage converters, also known as boost converters, are widely used to increase the voltage output from a power source.

- These converters operate by storing energy in an inductor during a switching period and releasing it to the load at a higher voltage.

- Step-up voltage converters are particularly useful when you need to power a device that requires a higher voltage than the available power source, such as stepping up a car battery’s 12V output to 24V.

Voltage Divider Circuits:

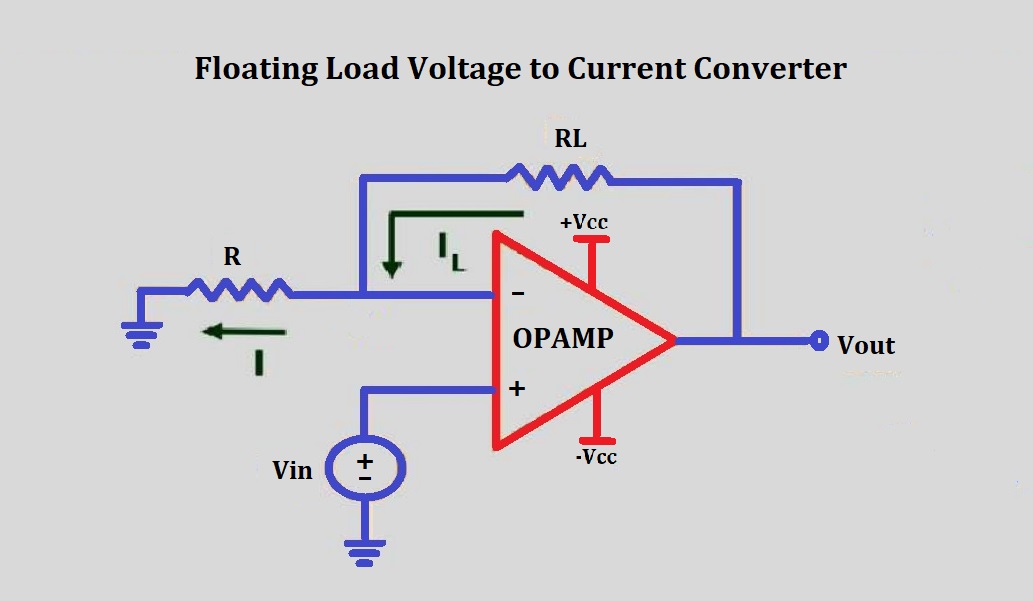

- Voltage divider circuits are simple and cost-effective methods for reducing voltage levels.

- These circuits consist of resistors connected in series, dividing the voltage across them proportionally based on their resistance values.

- By selecting appropriate resistor values, you can obtain a desired output voltage that is lower than the input voltage.

- Voltage divider circuits are commonly used to power devices that require lower voltage levels than the available power source.

Series Connection of Batteries:

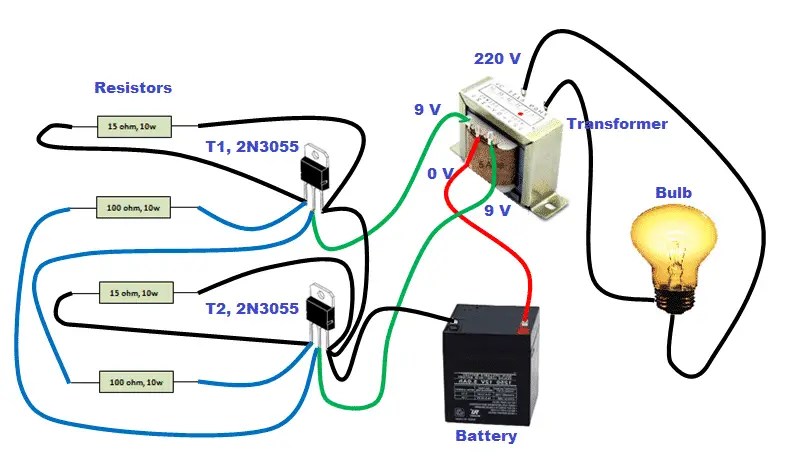

- When a single battery does not provide the required voltage, connecting batteries in series can increase the overall voltage output.

- In series connection, the positive terminal of one battery is connected to the negative terminal of another battery, creating a chain of voltages that add up.

- For example, connecting two 12V batteries in series results in a combined output of 24V.

- This method is commonly used in applications where higher voltages are needed, such as in RVs or solar power systems.

Using a Power Inverter:

- Power inverters are devices that convert DC (direct current) to AC (alternating current) voltage.

- They are often used to power devices that require AC voltage, such as household appliances or electronic equipment.

- Power inverters typically convert the DC voltage from a car battery or other DC power sources to AC voltage, allowing you to connect AC-powered devices directly.

- It’s important to select a power inverter with the appropriate power rating and waveform compatibility to ensure compatibility with your devices.

Each of these voltage conversion methods offers unique advantages and is suitable for different applications. The choice of method depends on factors such as the desired output voltage, power efficiency, portability, and specific requirements of the devices being powered.

Step-by-Step Guide: Using a Step-Up Voltage Converter

To power devices requiring higher voltage levels, a step-up voltage converter is a valuable tool. Here’s a concise step-by-step guide:

Step 1: Concept and Functioning

Understand how a step-up voltage converter converts lower input voltage to higher output voltage.Step 2: Materials and Tools

Gather the necessary materials and tools, including the converter module, wires, soldering iron, and multimeter.Step 3: Connect to Car Battery

Disconnect the car battery’s negative terminal, connect the input wires to the positive and negative terminals, and ensure secure connections.Step 4: Adjust Settings

Set the desired output voltage using the converter’s potentiometers or switches, following the manufacturer’s instructions.Step 5: Test Voltage Output

Use a multimeter to measure the output voltage and ensure stability under various load conditions.Step 6: Troubleshoot

Address common issues by checking connections, input voltage, settings, and inspecting for damage.Step 7: Safety Precautions

Prioritize safety by disconnecting power, wearing protective gear, and following guidelines.By following these steps, you can effectively use a step-up voltage converter to power your devices requiring higher voltage levels.

Step-by-Step Guide: Using a Voltage Divider Circuit

When it comes to adjusting voltage levels, a voltage divider circuit offers a reliable solution. Follow this detailed step-by-step guide to effectively use a voltage divider circuit:

Step 1: Concept and Functioning

Understand the fundamental concept of a voltage divider circuit and how it divides an input voltage into smaller output voltages based on resistor values.Step 2: Materials and Tools

Gather the necessary materials and tools, including resistors of appropriate values, a breadboard or PCB, wires, a multimeter, and a power source such as a car battery.Step 3: Connect to Car Battery

Establish a secure connection between the voltage divider circuit and the car battery, ensuring proper polarity and firm electrical contacts.Step 4: Calculate Resistor Values

Calculate the resistor values required to achieve the desired output voltage using the voltage divider equation, considering the input voltage and desired output voltage.Step 5: Test and Adjust Output Voltage

Measure the output voltage using a multimeter and compare it to the desired value. Adjust the resistor values if necessary to fine-tune the output voltage.Step 6: Troubleshoot

Identify and troubleshoot common issues such as incorrect resistor values, loose connections, or fluctuations in output voltage. Ensure the circuit is properly assembled and all components are functioning correctly.Step 7: Safety Precautions

Prioritize safety during the entire process. Use insulated tools, avoid touching live connections, and adhere to general electrical safety guidelines.By following this step-by-step guide, you can successfully utilize a voltage divider circuit to adjust voltage levels according to your specific requirements. Remember to exercise caution and double-check all connections and calculations to ensure a safe and accurate outcome.

Step-by-Step Guide: Using Series Connection of Batteries

When it comes to increasing voltage levels, utilizing a series connection of batteries can provide an effective solution. Follow this comprehensive step-by-step guide to successfully employ a series connection of batteries:

Step 1: Concept of Series Connection

Understand the concept of series connection, which involves connecting batteries end-to-end to increase the total voltage. In a series circuit, the positive terminal of one battery is connected to the negative terminal of the next battery.Step 2: Materials and Tools Required

Gather the necessary materials and tools for the task. This may include batteries of the same type and voltage rating, appropriate connecting wires, a voltmeter, and any necessary safety equipment.Step 3: Connecting Batteries in Series

Ensure the batteries are oriented correctly and align the positive terminal of one battery with the negative terminal of the next. Connect them securely using suitable wires or battery holders, ensuring proper polarity.Step 4: Testing the Voltage Output

Measure the total voltage output using a voltmeter connected across the terminals of the series-connected batteries. Confirm that the total voltage is equal to the sum of the individual battery voltages.Step 5: Troubleshooting Common Issues

Be aware of common issues that may arise, such as loose connections, mismatched battery types, or unequal voltage levels. Check all connections and ensure batteries are of the same type and rating.Step 6: Safety Precautions

Prioritize safety throughout the process. Avoid short circuits, handle batteries with care, and follow proper electrical safety guidelines. Use insulated tools and protective gear as necessary.By following this step-by-step guide, you can effectively utilize a series connection of batteries to increase the total voltage output. Remember to exercise caution, ensure proper battery compatibility, and double-check all connections and measurements. This method can be useful in various applications where a higher voltage is required, such as powering electronic devices or constructing battery banks for renewable energy systems.

Step-by-Step Guide: Using a Power Inverter

Harnessing the power of a power inverter is a convenient and efficient way to convert DC power from a car battery into AC power for various electronic devices. Follow this detailed step-by-step guide to successfully utilize a power inverter:

Step 1: Concept and Functioning

Understand the concept and functioning of a power inverter. A power inverter converts the direct current (DC) from a car battery into alternating current (AC), allowing you to power devices that require AC power.Step 2: Materials and Tools Required

Gather the necessary materials and tools for the task. This may include a power inverter of suitable wattage for your intended usage, appropriate cables, a voltmeter, and any necessary safety equipment.Step 3: Selecting an Appropriate Power Inverter

Choose an appropriate power inverter based on your power requirements. Consider the wattage capacity, input voltage range, and additional features such as surge protection and built-in safety mechanisms.Step 4: Connecting the Inverter to the Car Battery

Ensure the car’s engine is turned off and connect the power inverter to the car battery. Follow the manufacturer’s instructions regarding proper cable connections, ensuring proper polarity and secure connections.Step 5: Adjusting the Inverter Settings

Configure the inverter settings according to your specific needs. This may include adjusting the output voltage, selecting the appropriate waveform (such as pure sine wave or modified sine wave), and configuring any additional settings provided by the inverter.Step 6: Testing the Voltage Output and Stability

Using a voltmeter, measure the voltage output of the power inverter to verify its accuracy. Ensure the output voltage remains stable under different load conditions to guarantee consistent power supply to your devices.Step 7: Troubleshooting Common Issues

Familiarize yourself with common issues that may arise when using a power inverter, such as inadequate power supply, overheating, or device compatibility issues. Troubleshoot these issues by referring to the manufacturer’s guidelines or seeking professional assistance.Step 8: Safety Precautions

Prioritize safety throughout the process. Adhere to the safety guidelines provided by the inverter manufacturer, including proper grounding, avoiding overloading the inverter, and protecting the inverter from exposure to moisture or extreme temperatures.By following this step-by-step guide, you can effectively use a power inverter to convert DC power from a car battery into AC power for your electronic devices. Remember to choose the appropriate inverter, make secure connections, adjust the settings accordingly, and prioritize safety at all times. Whether you’re powering laptops, small appliances, or other devices on the go, a power inverter is a versatile tool that enhances your portable power capabilities.