Have you ever wondered what keeps your 1982 Alfa Romeo Spider smoothly navigating the twists and turns of the road? The rear differential is the most frequently overlooked yet critical component that contributes to the smooth driving experience you enjoy. Discover how rear differential maintenance is an overlooked aspect of Alfa Romeo Spider performance and how this often-neglected feature can affect the vehicle’s performance.

Maintaining proper rear differential alignment is the key to keeping your 1982 Alfa Romeo Spider at its best. This guide will help you identify early signs of trouble, as well as perform a maintenance routine step by step. Learn about the tools required, the correct fluid specifications, and the most common pitfalls to avoid while learning about fluid tools. Maintaining your Alfa Romeo Spider properly not only improves its performance but also aids its longevity.

Now, let’s get right to work on learning how to maintain the rear differential. This guide will teach you how to keep your Alfa Romeo Spider running smoothly, regardless of whether you’re a seasoned gearhead or a first-time owner. With our advice, you can learn how to properly care for your Alfa Romeo Spider, address common concerns, and keep it a symbol of driving excellence. As a result, how do you ensure your Alfa Romeo Spider’s rear differential will last the test of time?

Understanding the Rear Differential

In the intricate symphony of automotive engineering, the rear differential emerges as a silent maestro, orchestrating the harmonious movement of your 1982 Alfa Romeo Spider on the open road. At its core, the rear differential assumes the role of a mediator, distributing torque between the two rear wheels, allowing them to rotate at different speeds during turns. This pivotal function ensures that your Alfa Romeo Spider maintains stability and control, delivering a driving experience that seamlessly glides through twists and turns with finesse.

Now, let’s hone in on the specifics of the 1982 Alfa Romeo Spider rear differential design, a masterpiece crafted to complement the spirited nature of this iconic vehicle. The rear differential in the 1982 Alfa Romeo Spider is a bevel gear type, a design choice that optimizes performance and handling. This configuration allows for efficient power distribution, ensuring that each wheel receives the necessary torque for optimal traction, particularly crucial during acceleration and cornering maneuvers. The precision of this design is emblematic of Alfa Romeo’s commitment to engineering excellence.

Amidst this mechanical prowess, the importance of regular maintenance emerges as the linchpin for ensuring the longevity of the rear differential and, by extension, the enduring performance of the 1982 Alfa Romeo Spider. Imagine the rear differential as the vigilant guardian of your vehicle’s well-being, requiring periodic attention to function at its best. Routine maintenance involves not only replenishing the differential fluid but also conducting thorough inspections to identify potential issues before they escalate.

Ensuring Smooth Operations

Maintaining the rear differential transcends mere mechanical upkeep; it’s a commitment to preserving the soul of your Alfa Romeo Spider. Regular fluid changes, typically recommended every 30,000 to 50,000 miles, become the lifeblood that sustains the gears and bearings within the differential housing. Neglecting this aspect could lead to increased friction, heightened temperatures, and ultimately, premature wear and tear.A Glimpse into Longevity

Delving deeper into the realm of longevity, proper rear differential maintenance is a proactive measure against potential malfunctions. By adhering to a meticulous schedule, you not only extend the lifespan of the differential components but also safeguard the overall drivetrain integrity. Picture it as an investment in the enduring legacy of your 1982 Alfa Romeo Spider, a commitment to relishing the thrill of the road for years to come.Identifying Signs of Issues

In the intricate dance of automotive components, the rear differential of your 1982 Alfa Romeo Spider plays a crucial role, ensuring a smooth and responsive drive. However, like any finely tuned mechanism, it occasionally sends distress signals when all is not well beneath the surface. To maintain the impeccable performance of your vintage Alfa Romeo, it is imperative to adeptly identify these warning signs.

Unraveling the Symphony: Unusual Sounds or Vibrations

As you embark on a journey with your Alfa Romeo Spider, pay heed to the auditory nuances emanating from the rear of the vehicle. Unusual sounds, such as whining, clunking, or grinding noises, can be indicative of potential rear differential issues. These auditory cues, akin to the vehicle’s distress signals, necessitate immediate attention. Vibrations, especially during turns or acceleration, could signify imbalances within the differential system. Regularly tuning your ears to these symphonic whispers allows for early detection, a preemptive measure to safeguard against escalating mechanical challenges.

Tracing the Footprints: Leaks and Fluid Level Discrepancies

In the meticulous care of your Alfa Romeo Spider, periodic visual inspections become an imperative ritual. Keep a vigilant eye for telltale signs of leaks around the rear differential housing. These leaks, often manifesting as dark spots or puddles beneath the vehicle, could be attributed to a failing seal or gasket. Simultaneously, monitor the fluid level within the differential. A significant drop in fluid levels might signify a potential leak or, more ominously, internal issues. Consistent vigilance in tracing these fluid footprints ensures the early detection of problems, preventing a minor inconvenience from snowballing into a major predicament.

Decoding Anomalies: Performance Irregularities

The nuanced performance of your Alfa Romeo Spider serves as a barometer of its mechanical well-being. Any irregularities in acceleration, deceleration, or overall responsiveness demand meticulous scrutiny. If you perceive a noticeable drag, hesitation, or a delay in power delivery, these may be indicators of impending rear differential issues. The vehicle’s agility and responsiveness are quintessential aspects of the Alfa Romeo experience, and any deviations from the norm warrant a thorough investigation. Prompt identification and resolution of these anomalies ensure that your Alfa Romeo Spider continues to grace the road with its characteristic finesse.

In essence, understanding and recognizing these signs of rear differential issues contribute significantly to the proactive maintenance of your 1982 Alfa Romeo Spider. By attuning your senses to the auditory, visual, and performance cues, you become the vigilant custodian of your vehicle’s mechanical symphony. Embark on each drive with an acute awareness of these potential signals, unraveling the intricacies beneath the hood, and preserving the legacy of your Alfa Romeo Spider with a discerning eye and an attuned ear.

Necessary Tools and Materials

Embarking on the journey of rear differential maintenance for your 1982 Alfa Romeo Spider requires a meticulous selection of tools and materials, akin to assembling the arsenal for a mechanical quest. The success of this venture lies not just in the precision of execution but also in the choice of implements. Here’s a comprehensive guide, demystifying the necessary tools, recommended fluid types, and imperative safety precautions.

The Essential Toolkit

When venturing into the realm of rear differential maintenance, equipping yourself with the right tools is akin to preparing for a skilled endeavor. Here’s a curated list to ensure you’re armed for the task:

- Jack and Jack Stands: Elevating your Alfa Romeo Spider securely is the first step, and a reliable jack with corresponding stands is indispensable.

- Wrench Set: A versatile set of wrenches, including both open-end and socket wrenches, ensures you’re prepared for various bolts and nuts.

- Torque Wrench: Precision matters in tightening critical components like the drain plug, making a torque wrench a non-negotiable tool.

- Drain Pan: An adequately sized drain pan is essential for collecting the old differential fluid during the maintenance process.

- Funnel: A clean and efficient fluid refill necessitates a funnel to prevent spills and ensure accurate pouring.

- Rags and Gloves: As the hands-on custodian of your Alfa Romeo Spider, protecting yourself with gloves and having rags on standby for potential spills is imperative.

Fluid Wisdom: Types and Quantities

The lifeblood of the rear differential is its fluid, and the choice thereof significantly impacts the performance and longevity of this critical component. Opt for a high-quality gear oil with the proper viscosity, typically specified in the vehicle’s manual. In the case of the 1982 Alfa Romeo Spider, a GL-5 gear oil with a viscosity of 80W-90 is often recommended.

Quantity Guidelines: The capacity of the 1982 Alfa Romeo Spider’s rear differential is around 1.8 quarts or approximately 1.7 liters. It’s advisable to purchase slightly more than this amount to account for any residual fluid that may remain in the differential after draining.

Brand Considerations: While there are several reputable brands in the market, consider factors such as viscosity, additives, and manufacturer recommendations. Brands like Mobil 1, Valvoline, and Royal Purple often find favor among automotive enthusiasts.

Safeguarding the Journey: Safety Precautions

Undertaking rear differential maintenance is not merely a mechanical task; it’s a responsibility that demands a commitment to safety. Here’s a checklist to fortify your safety measures:

- Safety Glasses: Shield your eyes from potential splashes or debris with a pair of safety glasses.

- Work in a Well-Ventilated Area: Ensure proper ventilation to disperse fumes and prevent inhalation of potentially harmful gases.

- Parking Brake Engagement: Before lifting your vehicle, engage the parking brake to prevent any unintended movement.

- Use Sturdy Jack Stands: Securely position jack stands under the vehicle, providing an additional layer of safety during the maintenance process.

Armed with this arsenal of knowledge, tools, and precautions, you’re poised to embark on a journey of rear differential maintenance that not only ensures the optimal performance of your 1982 Alfa Romeo Spider but also reflects a commitment to the longevity and well-being of your cherished vehicle. The marriage of precision, quality, and safety transforms this mechanical endeavor into a symphony of automotive care, ensuring your Alfa Romeo Spider continues to navigate the roads with poise and prowess.

Preparing for Maintenance

As you step into the realm of rear differential maintenance for your 1982 Alfa Romeo Spider, envision it as a meticulous choreography, where each step is a graceful movement towards the symphony of a well-maintained vehicle. Proper preparation is the overture to this automotive performance, ensuring not only the safety of the conductor, but the harmonious function of every mechanical note. Let’s delve into the intricacies of preparing for rear differential maintenance.

Lifting and Securing: The Vehicle Ballet

Before the mechanical ballet ensues, the Alfa Romeo Spider must gracefully ascend to the stage. Safely lifting and securing the vehicle becomes the opening act, a delicate ballet where safety takes center stage:

- Utilize a Hydraulic Jack: Lift the vehicle with a reliable hydraulic jack, ensuring a steady ascent without compromising safety.

- Position Sturdy Jack Stands: Once elevated, strategically position robust jack stands beneath the vehicle, guaranteeing stability during the maintenance performance.

- Engage the Parking Brake: As the vehicle gracefully hovers above the ground, engage the parking brake, adding an extra layer of security against unintended movement.

Spotlight on Precision: Locating the Rear Differential and Drain Plug

With the Alfa Romeo Spider elevated, the spotlight shifts to the stars of this automotive show—the rear differential and its elusive drain plug. Precision is key as you navigate the mechanical constellations:

- Consult the Owner’s Manual: Before the grand reveal, consult the vehicle’s owner’s manual, unraveling the celestial map to the rear differential’s exact location.

- Crawl beneath the Vehicle: Gracefully slide beneath the vehicle, equipped with a flashlight to illuminate the rear differential’s clandestine position.

- Identify the Drain Plug: In this cosmic quest, locate the drain plug—a small yet pivotal detail that marks the initiation point of the maintenance ritual.

Gathering the Ensemble: Essential Materials and Tools

With the stage set, it’s time to gather the ensemble cast of essential materials and tools. Imagine it as a backstage preparation, where each tool is a performer contributing to the mechanical symphony:

- Wrench Set: A versatile set of wrenches, both open-end and socket varieties, emerges as the prima donna, orchestrating the intricate dance of nuts and bolts.

- Drain Pan: Positioned like a vigilant guardian, the drain pan awaits its role in collecting the old differential fluid, ensuring a tidy performance.

- Funnel: A supporting actor, the funnel steps in for a seamless fluid refill, preventing spills and enhancing accuracy.

- Safety Gear: Like costumes for the performers, safety gloves and glasses take center stage, shielding the conductor from potential splashes and debris.

In the meticulous preparation for rear differential maintenance, envision yourself as the choreographer of this automotive ballet—a conductor orchestrating the movements with precision and care. As the curtain rises, the hydraulic jack gracefully elevates the Alfa Romeo Spider, the spotlight illuminates the rear differential and drain plug, and the ensemble of tools and materials assembles backstage, ready to perform their part in the automotive symphony. This, dear reader, is the prelude to a well-orchestrated maintenance routine, setting the stage for the continued excellence of your 1982 Alfa Romeo Spider.

Step-by-Step Fluid Drainage

Navigating the intricacies of rear differential maintenance for your 1982 Alfa Romeo Spider requires a choreographed approach, and the fluid drainage process takes center stage in this vehicular ballet. Picture it as a meticulous dance where each step contributes to the symphony of a well-maintained differential, ensuring peak performance and longevity.

The Dance Begins: Properly Draining the Old Fluid

Position the Drain Pan: Begin by positioning a drain pan beneath the rear differential. Think of it as setting the stage for the grand performance, anticipating the fluid’s descent.

Loosen the Drain Plug: With a precise move, use the appropriate wrench to loosen the drain plug. This step is akin to the first graceful movement of a dancer, initiating the fluid’s gradual exit.

Allow Complete Drainage: Like a fluidic ballet, let the old differential fluid cascade into the drain pan completely. Patience is key, as a thorough drainage sets the stage for a fresh performance.

Inspecting Elegance: Examining the Drain Plug for Abnormalities

Retrieve the Drain Plug: With the old fluid gracefully making its exit, retrieve the drain plug. It’s time for a close inspection, much like scrutinizing the details of a dance costume for any imperfections.

Examine for Wear and Tear: Inspect the drain plug for any signs of wear, tear, or abnormality. This step is equivalent to checking the dancer’s costume for frays or irregularities that might impact the performance.

Cleanse and Prepare: Cleanse the drain plug meticulously, preparing it for its encore. This ensures that the plug, like a performer in the spotlight, is ready to resume its role in maintaining the differential’s fluid equilibrium.

The Grand Finale: Ensuring a Complete and Clean Drainage Process

Wipe and Clean the Surroundings: Just as a dancer exits the stage with grace, wipe and clean the surrounding area of the rear differential. A clean stage ensures that the ensuing performance is free from any residual debris.

Tighten the Drain Plug: With the drainage process now a choreographed memory, tighten the drain plug with precision. Think of it as the final movement in a dance routine, ensuring every component is securely in place.

Prepare for Fluid Refill: As the fluid drainage concludes, prepare for the subsequent act – fluid refill. Like a dancer preparing for the next routine, this step ensures a seamless transition towards replenishing the differential with fresh, high-quality fluid.

In this meticulously orchestrated fluid drainage process, each step is a note in the symphony of rear differential maintenance. The dance between draining the old fluid, inspecting the drain plug, and ensuring a complete and clean process is a ballet of automotive care, contributing to the longevity and optimal performance of your 1982 Alfa Romeo Spider. As the curtain falls on this act, the rear differential stands poised for its next performance on the open road, ready to navigate with the elegance and precision of a seasoned dancer.

Fluid Replacement

Embarking on the fluid replacement journey for the revered 1982 Alfa Romeo Spider’s rear differential is akin to selecting the perfect elixir for a treasured artifact. Choosing the right fluid is a nuanced decision that underlines the commitment to the vehicle’s optimal performance and longevity. As the orchestration of this automotive symphony unfolds, a step-by-step guide to refilling the rear differential emerges, ensuring a seamless transition from old to new. Finally, the curtain falls on this act with a meticulous check for proper fluid levels, validating the success of the fluid replacement endeavor.

The Elixir of Performance: Choosing the Right Fluid

Consult the Owner’s Manual: The first page in the playbook of fluid replacement is the vehicle’s owner’s manual. It unfolds the specifics of the 1982 Alfa Romeo Spider’s fluid requirements, outlining the viscosity, additives, and brand recommendations. This step is akin to consulting an ancient manuscript to unlock the secrets of longevity.

Selecting the Appropriate Fluid: Armed with the knowledge from the manual, venture into the realm of high-quality gear oils. Brands like Mobil 1, Valvoline, and Royal Purple often take center stage, boasting formulations that align with the Alfa Romeo Spider’s intricate mechanical dance.

Consider the GL Rating: The GL rating is the musical note that resonates with the Alfa Romeo Spider’s rear differential. Opt for a GL-5 gear oil, indicating suitability for hypoid gears and ensuring optimal performance in the intricate dance of the differential components.

The Dance of Refilling: A Step-by-Step Guide

Position the Funnel: Like a conductor preparing to channel the first notes of a symphony, position a funnel at the fill hole of the rear differential. This ensures a seamless and controlled pour of the chosen fluid.

Pouring with Precision: With the funnel in place, pour the selected fluid into the rear differential. Picture it as pouring a rare and precious liquid into a chalice, each drop contributing to the rejuvenation of the mechanical essence.

Check the Capacity: Refer to the owner’s manual to determine the rear differential’s fluid capacity. This is a critical step to avoid overfilling or underfilling, ensuring that the fluid level aligns perfectly with the manufacturer’s specifications.

Ensuring Harmony: Checking for Proper Fluid Levels

Utilize the Dipstick or Inspection Plug: Just as a maestro uses a baton to measure the intensity of a musical crescendo, utilize the dipstick or inspection plug to gauge the fluid level. The dipstick emerges as the conductor’s baton, providing a visual cue for the fluid’s alignment.

Leveling the Vehicle: Ensure the Alfa Romeo Spider rests on a level surface before checking fluid levels. This leveling act is equivalent to tuning an instrument, creating the optimal conditions for an accurate fluid level assessment.

Adding or Draining if Necessary: If the fluid level deviates from the specified range, take corrective measures. Add more fluid if it’s below the recommended level or drain excess fluid if it surpasses the capacity. This step mirrors the fine-tuning required to achieve the perfect pitch in a musical composition.

In this fluid replacement symphony, choosing the right fluid, following a meticulous refilling guide, and checking for proper fluid levels are the crescendos that contribute to the longevity and optimal performance of the 1982 Alfa Romeo Spider. As the final notes echo beneath the vehicle, the rear differential stands rejuvenated, ready to navigate the roads with the grace and precision of a well-composed masterpiece.

Sealing and Securing

As the meticulous maintenance journey of your 1982 Alfa Romeo Spider’s rear differential reaches its penultimate act, the spotlight turns to the crucial steps of sealing and securing. The dance of replacing the drain plug and ensuring an impeccable seal sets the stage for the differential’s encore performance on the open road. The torque specifications for the drain plug emerge as the choreographic notes, dictating the precision required to maintain the differential’s equilibrium. As the final crescendo, double-checking for any potential leaks ensures that the symphony of maintenance reaches a flawless conclusion.

The Ballet of Sealing: Replacing the Drain Plug and Ensuring a Secure Seal

Retrieve the Drain Plug: With the old fluid replaced by the elixir of performance, delicately retrieve the drain plug. Picture it as the return of a key performer to the stage, ready to resume its role in the automotive ballet.

Inspect the Drain Plug Threads: Before the grand finale, inspect the threads of the drain plug. This step is akin to ensuring the dancer’s shoes are laced securely, guaranteeing a secure grip on the stage.

Hand-Tighten the Drain Plug: Begin the sealing ritual by hand-tightening the drain plug into its designated position. Feel the threads align with the grace of a dancer finding their rhythm, setting the stage for the final act.

Torque Wrench Precision: Equip a torque wrench with the precision of a conductor’s baton, ensuring each note is played at the exact intensity. Follow the manufacturer’s specifications for torque, tightening the drain plug to the specified pound-feet, securing the fluid’s containment with a symphony of precision.

The Symphonic Notes: Torque Specifications for the Drain Plug

Reference the Owner’s Manual: Open the owner’s manual as if consulting a sheet of musical notes, finding the specific torque requirements for the drain plug. This step is akin to following the musical score to maintain harmony.

Select the Appropriate Torque Value: Like selecting the perfect pitch for a musical note, choose the appropriate torque value on the wrench, aligning with the manufacturer’s specifications. This ensures the drain plug is tightened to perfection, preventing over-torquing or under-torquing.

Apply Torque in Gradual Increments: Release the torque in gradual increments, much like a musician modulating the volume for a seamless transition between notes. This gradual application guarantees a secure seal without undue stress on the components.

The Final Crescendo: Double-Checking for Any Potential Leaks

Inspect the Sealed Area: With the drain plug securely in place, conduct a visual inspection of the sealed area. Imagine it as the conductor surveying the orchestra for any out-of-place instruments, ensuring every component is harmoniously aligned.

Utilize a Clean Rag: Wipe the area around the drain plug with a clean rag, resembling the meticulous care a musician gives to their instrument. This step unveils any subtle signs of leakage, guaranteeing a pristine performance.

Perform a Trial Run: Before the curtain falls on the maintenance symphony, embark on a trial run. Start the engine and let it idle for a few minutes, observing the sealed area for any emerging leaks. This dynamic test ensures that the sealing and securing act withstands the pressures of operational dynamics.

In the closing act of sealing and securing, the 1982 Alfa Romeo Spider’s rear differential emerges as a well-tuned instrument, ready to take center stage on the road. The dance of replacing the drain plug, adhering to torque specifications, and double-checking for leaks transforms the maintenance routine into a symphony of automotive excellence. As the curtain descends on this maintenance masterpiece, the rear differential stands as a testament to meticulous care, poised to navigate the highways with the grace and security of a well-executed performance.

Testing and Quality Assurance

Embarking on the final leg of the meticulous rear differential maintenance journey for the 1982 Alfa Romeo Spider, the spotlight shifts to testing and quality assurance. Imagine this phase as the grand finale, where the performance of your vehicle takes center stage, validated by a brief road test and a thorough examination of its mechanical heartbeat. Listening keenly for abnormal sounds or vibrations and verifying proper fluid circulation become the maestro’s cues, ensuring that the symphony of maintenance concludes with a flawless performance on the road.

The Road Test Symphony: Assessing Performance

Engage in a Brief Drive: Transitioning from the maintenance stage to the grand performance, engage in a brief road test. Picture it as the inaugural notes of a musical composition, where the vehicle’s performance unfolds on the road as if played by a skilled musician.

Evaluate Acceleration and Deceleration: Assess the acceleration and deceleration phases during the road test, much like scrutinizing the dynamics of a musical crescendo. This evaluation ensures that the differential responds seamlessly to varying speeds and driving conditions.

Check for Steering Responsiveness: Just as a conductor ensures every instrument in the orchestra responds promptly, gauge the steering responsiveness. This step validates that the rear differential harmonizes with the vehicle’s steering, contributing to a smooth and controlled driving experience.

Listening for Mechanical Harmony: Abnormal Sounds or Vibrations

Focus on Auditory Cues: As the vehicle glides on the road, focus on auditory cues. Listen keenly for any abnormal sounds or vibrations, akin to a conductor detecting a discordant note in an otherwise harmonious symphony.

Identify Whining or Grinding Noises: Pay attention to potential whining or grinding noises emanating from the rear differential. These could be indicative of mechanical stress or irregularities, warranting further inspection and fine-tuning.

Address Any Detected Abnormalities: If abnormal sounds or vibrations are detected, address them promptly. It’s analogous to a musician tuning their instrument mid-performance, ensuring that the mechanical components are in perfect harmony.

Fluid Circulation: Verifying the Lifeblood of the System

Inspect for Fluid Leaks: During the road test interlude, inspect the area around the rear differential for any signs of fluid leaks. This visual check ensures that the lifeblood of the differential, the recently replaced fluid, circulates without seepage.

Monitor Temperature Levels: Keep a watchful eye on temperature levels. Excessive heat could be a red flag, mirroring a conductor monitoring the temperature of the orchestra to prevent instruments from going out of tune.

Ensure Proper Circulation: Verify that the fluid circulates optimally within the differential. This is akin to ensuring that the musical notes flow seamlessly, confirming that each component operates in concert with the others.

In this culminating act of testing and quality assurance, the 1982 Alfa Romeo Spider emerges as a finely tuned instrument, ready to serenade the open road with the symphony of a well-maintained rear differential. The road test becomes the grand stage, and the vigilant listening for abnormal sounds or vibrations, along with the verification of proper fluid circulation, serves as the conductor’s baton, orchestrating a flawless performance. As the curtain falls on this maintenance masterpiece, your vehicle stands poised for its next journey, a testament to the meticulous care and quality assurance invested in its mechanical symphony.

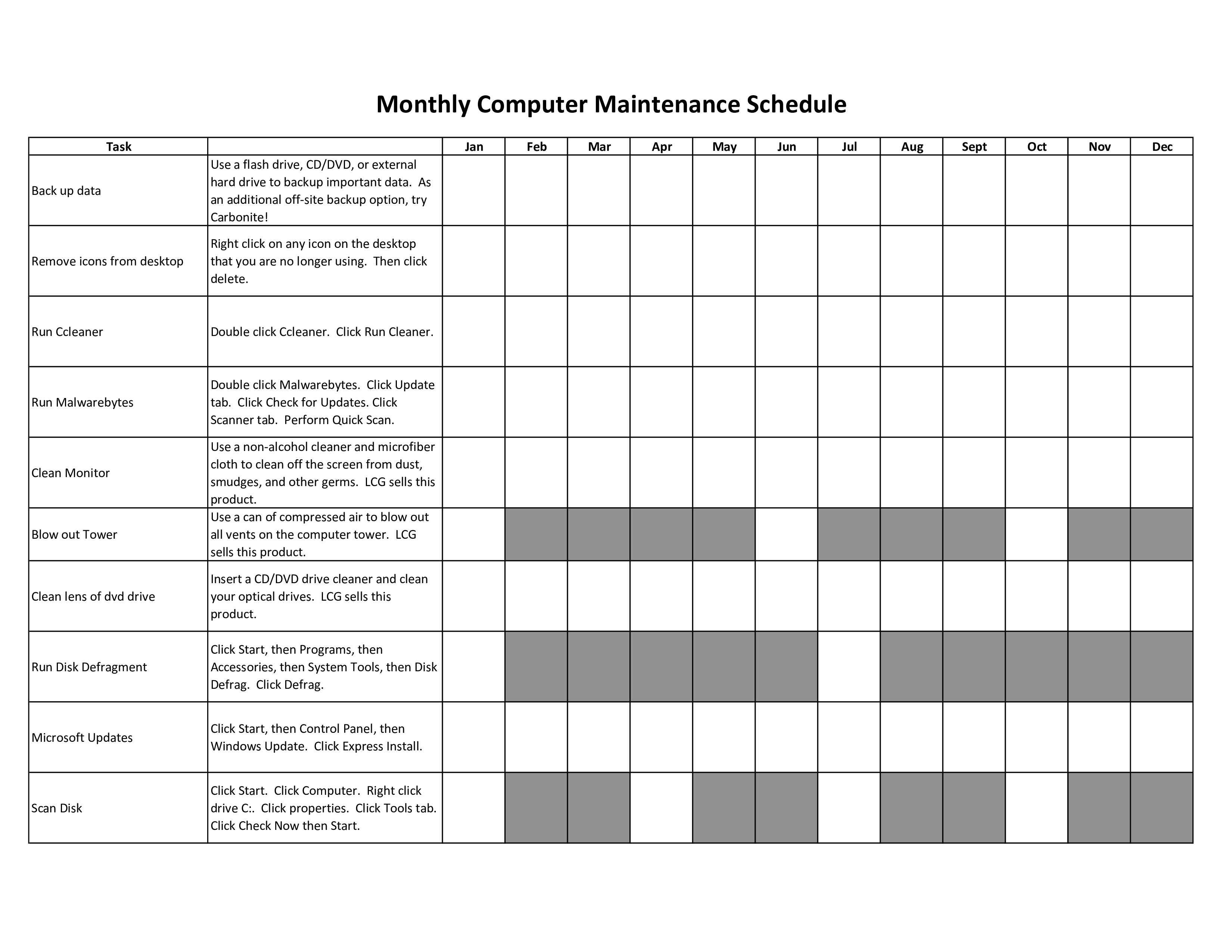

Maintenance Schedule

Maintaining the optimal performance of your 1982 Alfa Romeo Spider’s rear differential is not merely a task; it’s a commitment to the longevity and efficiency of your vehicle. Establishing a proactive maintenance schedule ensures that your rear differential operates seamlessly, contributing to a smooth and enjoyable driving experience. Consider this schedule as the conductor’s score, guiding you through the harmonious intervals of fluid replacement, mileage-based checkpoints, and thorough inspections.

Regular Rear Differential Maintenance: A Symphony of Care

Recommendation for Frequency: Commence your maintenance symphony by recommending a regular rear differential maintenance schedule. Encourage vehicle owners to adhere to a routine, suggesting intervals at which they should perform checks and replacements. This commitment parallels the dedication a musician has to their craft, practicing regularly to maintain skill and finesse.

Mileage-Based Fluid Replacement Guidelines: Like the cadence of a musical composition, provide mileage-based guidelines for fluid replacement. Advise owners to replace the differential fluid at specific intervals, ensuring it remains clean and effective in reducing friction and heat. This recommendation mirrors a musician changing their strings or reeds, ensuring the instrument produces optimal sound.

Additional Checks During Routine Inspections: Elevate the maintenance schedule by incorporating additional checks during routine inspections. These checks encompass scrutinizing the differential for leaks, inspecting the seals, and assessing the overall mechanical health. This holistic approach mirrors the meticulous inspection a musician conducts on their instrument, ensuring every component is in pristine condition.

Maintenance Milestones: A Symphony Unfolding Over Time

Every 30,000 Miles: As the initial movement in this maintenance symphony, recommend a comprehensive inspection of the rear differential at 30,000 miles. This milestone serves as a checkpoint for fluid replacement, seal inspections, and an overall assessment of the differential’s performance. It’s akin to the first act of a musical performance, setting the stage for what follows.

Every 60,000 Miles: Progressing through the movements, emphasize another pivotal checkpoint at 60,000 miles. At this juncture, advocate for a thorough fluid replacement, ensuring the differential continues to operate with optimal efficiency. This milestone is comparable to a musical interlude, a moment of reflection and adjustment before the performance resumes.

Every 90,000 Miles: As the final crescendo in this symphony of maintenance, advocate for a comprehensive inspection at 90,000 miles. This milestone marks a holistic assessment, including fluid replacement, seal checks, and a detailed examination of the differential’s components. It’s equivalent to the grand finale, ensuring the rear differential concludes its performance on a high note.

In crafting and adhering to this maintenance schedule, vehicle owners orchestrate a melody of care for their 1982 Alfa Romeo Spider’s rear differential. Like a musician attending to their instrument with precision and dedication, regular maintenance becomes a ritual, preserving the mechanical harmony of the vehicle. This proactive approach not only enhances performance but also prolongs the lifespan of the rear differential, ensuring it remains a key player in the symphony of your driving experience.

Common Mistakes to Avoid

Navigating the maintenance of your 1982 Alfa Romeo Spider’s rear differential can be akin to a delicate dance – precise movements are crucial to ensuring the longevity and optimal performance of this essential automotive component. However, amid the intricate steps, there are common missteps that vehicle owners must be vigilant to avoid. Understanding these potential pitfalls is tantamount to orchestrating a seamless automotive performance.

The Overfilling and Underfilling Tango

Overfilling: Imagine a dance partner leading with too much force; similarly, overfilling the rear differential can lead to excessive pressure within the system. This can result in leaks, increased friction, and potential damage to seals. As such, caution vehicle owners against the temptation to pour in more fluid than recommended, emphasizing precision over abundance.

Underfilling: On the flip side of the dance floor, underfilling is a misstep that can lead to inadequate lubrication, causing increased friction and heat. This lack of fluid can also result in premature wear and tear on the differential components. Guide vehicle owners to follow manufacturer specifications diligently, ensuring the fluid level is neither too high nor too low – a harmonious balance for optimal performance.

The Fluid Types Waltz

- Choosing the Incorrect Fluid: Selecting the wrong fluid for the rear differential is akin to choosing the wrong dance partner – it may seem compatible initially, but the consequences can be detrimental. Different vehicles have varying specifications for fluid types, viscosities, and additives. Emphasize the importance of consulting the owner’s manual or seeking professional advice to ensure the selected fluid aligns with the manufacturer’s recommendations, preventing potential damage to the differential components.

The Neglecting Signs Foxtrot

- Ignoring Warning Signs: The dance of maintenance requires attentive partners, and the vehicle’s owner must be attuned to signs of potential issues. Unusual sounds, vibrations, or fluid leaks are the subtle cues that something might be amiss with the rear differential. Neglecting these warning signs is akin to dismissing a partner’s cues in a dance – it can lead to missteps, or in the case of a vehicle, more severe damage over time. Encourage vehicle owners to address these signs promptly, seeking professional assistance if needed, to avoid exacerbating potential problems.

In crafting an informative guide on rear differential maintenance, highlighting these common mistakes is crucial. It equips vehicle owners with the knowledge needed to sidestep potential pitfalls, ensuring their automotive performance remains a graceful and efficient affair. By adhering to the recommended fluid levels, selecting the right fluid types, and staying attuned to warning signs, vehicle owners can navigate the maintenance dance floor with confidence, ensuring a smooth and enduring performance from their 1982 Alfa Romeo Spider’s rear differential.