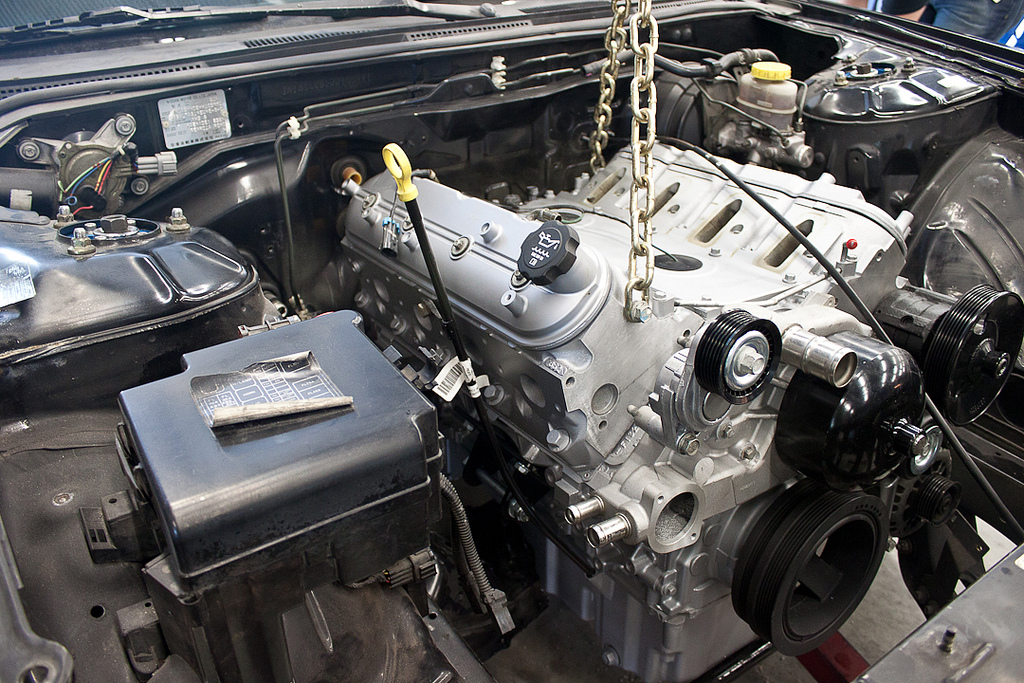

Installing an Oldsmobile 350 engine into a Pontiac Firebird is a great way to increase the power and performance of the vehicle. This swap is a relatively straightforward process, but it does require some mechanical knowledge and a fair amount of time to complete. You’ll need to consider the compatibility of the engine and the car, as well as the necessary modifications and hardware to make the swap successful. In this article, we will provide an overview of the steps needed to mount an Oldsmobile 350 engine into a Pontiac Firebird, including information on the parts and tools required, as well as any modifications that may be necessary. With the right knowledge and preparation, this engine swap can be accomplished in no time.

Are All Sbc Motor Mounts The Same?

There is a common misconception that all standard big- and Chevy engine mounting systems are interchangeable. It is true that the cylinder-block engine mounting bolt patterns are identical, and they are located equidistant from the front and rear bellhousing faces.

Understanding The Difference: Small Block Chevy Vs Ls Motor Mounts

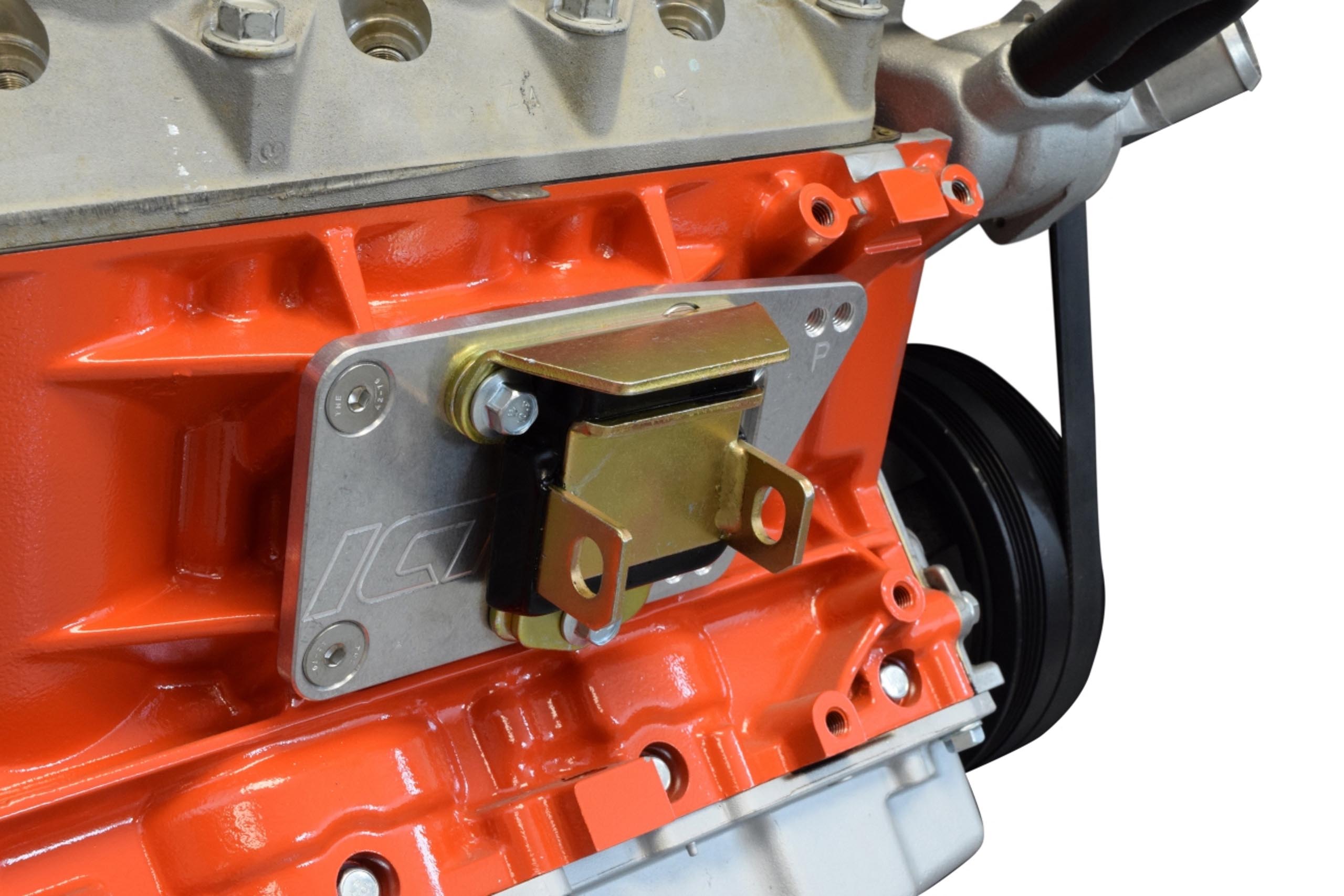

When it comes to engine mounts, size is more important than quantity. The look of small block Chevy and LS motor mounts may appear similar, but they do not work in concert. A four-bolt mount that bolts to the engine block’s side is the more common option for the LS motor mount, while the standard three-bolt Chevy small-block mount is the most common. Motor mounts, also known as engine mounts, are used to connect the car body and the engine and typically come in rubber or similar materials to avoid metal-to-metal contact. A big block engine is larger and heavier than a small block engine, and it has larger bores, longer strokes, larger valves, and ports, allowing it to produce more power. Tuning an LS engine to an early-style three-bolt engine mount is the most common solution for the size difference between engines.

Is Upgrading Your Engine Mounts Even Worth It?

You must be able to put in performance. drivetrain mounts’ primary function is to reduce the noise and vibration generated by the car’s mechanicals to the cabin, but they can have a negative impact on power delivery, shifting, and even handling.

Don’t Overlook Motor Mount Maintenance – Replacing Before Damage Occurs

A motor mount replacement should not be overlooked; it is critical. Failure to do so may result in serious engine damage and a decrease in performance. While solid engine mounts provide the most power, they are best suited for competition because they result in the most vibration and noise. Motor mounts need to be replaced, and the cost can be quite high. As a result, it is critical to inspect any signs of a faulty motor mount and replace it as soon as possible.

Do All Ls Engines Use The Same Motor Mounts?

Mounts on all LS-series engines come standard with the same mounting bosses. Trans Dapt, Holley, and Chris Alston’s Chassisworks are a few aftermarket companies that make adapter mounts to install an LS into almost any vehicle.

Are Lt And Ls Motor Mounts The Same?

There are numerous differences between the LS and LT engines, but the mount embossments on the block line are in line with the block center line on both engines. The location is different from a traditional Chevy shop in the first generation of the car. The four-bolt pad is also used.

Are All Chevy Motor Mounts The Same?

They are not. Motor mounts and transmission mounts are the four most common types of mounts in a motor. To ensure that the mount is properly positioned, it is critical to specify its position in your purchase.

Are All Ls Motors The Same Size?

The majority of LS cranks are made up of the same design, with a rod length of 2.10 inches and a main journal length of 2.75 inches. The exception is the forged steel crank LSA9, which is the only one with an iron finish.

Can Motor Mounts Be Installed Incorrectly?

If the mount is not properly positioned, you may experience unusual driveline conditions such as heavy banging when you travel over bumps caused by the slip yoke slamming into the transmission’s tail shaft, or you may be unable to line up bolt holes.

Can You Install Motor Mounts Wrong?

When you notice signs that your engine mounts are in need of replacement, you should bring your vehicle to a reputable and qualified engineer right away. Although you can install engine mounts yourself, we recommend that you bring your vehicle to a reputable and qualified engineer as soon as you notice the signs.

Do Motor Mounts Make Your Car Jerk?

When changing gears, the engine mounts are subjected to vibrations in addition to being damaged, and a transmission attached to the engine mounts also causes jerks and jolts. There is a chance of detecting this jerk when you are driving at a higher speed or when you change gears.

Do Motor Mounts Affect Idle?

As a result, when one of your engine mounts is damaged or worn out, the engine will feel much stronger. It’s especially noticeable when you don’t hear any of the other wonderful road noises and vibrations that can distract you at idle.