The PCV valve (positive crankcase ventilation) is a critical part of any vehicle’s emissions system, and it is important to make sure that it is in good working order. Replacing the PCV valve on a 2005 Pontiac Montana is a relatively simple process that can be done in a short amount of time. In this guide, we will discuss the steps necessary to remove the old PCV valve and install the new one, as well as how to ensure that the job is done properly. With the correct tools and a bit of patience, you can get your Pontiac Montana back to running in no time.

How Long Does It Take To Replace Pcv Valve?

Replacing a PCV valve typically takes about 30 minutes, depending on the make and model of the vehicle. The process involves locating the valve, removing the old valve, and installing a new valve. If the PCV valve is located in a difficult to reach area, the process may take longer. To ensure the job is done correctly, it is best to consult a qualified mechanic or repair shop.

Driving with a damaged PCV valve for more than 12 hours can be hazardous, especially if you have children. Failure to ventilate the crankcase, or to accumulate gas in it without proper ventilation, can result in the formation of sludge and acid, resulting in engine damage and air pollution. In addition, the engine’s lifespan will be shortened. It is critical to replace the PCV valve as soon as possible in order to avoid these issues. Failure to do so can result in potentially dangerous situations. As a result, you must take certain precautions to keep your vehicle running efficiently and safely.

How To Remove A Stuck Pcv Valve

If you’re trying to remove a stuck PCV valve, the best thing to do is to first keep the engine off and cool. Once it’s cooled, you should use a screwdriver to loosen the valve from the valve cover. If that doesn’t work, you may need to use a valve spring compressor to remove the valve. Once the valve is released, you should make sure to clean the area where the valve was attached, and then lubricate the new valve before reinstalling it. Finally, make sure to tighten the valve securely before turning the engine back on.

Maintain Your Pcv Valve For Optimal Engine Performance

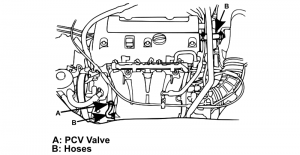

The PCV valve is one of the most important components in maintaining the health of your engine. To keep the engine running smoothly and efficiently, the PCV valve must remove air and combustible gases from the crankcase. However, when the PCV valve becomes open or the system hose is disconnected or ruptured, the vacuum leak can lead to severe problems. To avoid such issues, you must first learn how to inspect and maintain your PCV valve. If the PCV valve is connected, loosen the hose clamp if necessary, and then pull the little L-shaped housing off the end of the valve. When a PCV valve is threaded into place, it is usually held in place with a rubber grommet; when it is held in place with a rubber grommet, it can be pulled free. After you have access to the valve, check it for any damage, dirt, or debris that may have formed. If everything appears to be in order, the valve can be reinstalled. If the PCV valve becomes stuck, it can cause a variety of engine issues, including rough running and stalling. Furthermore, due to increased airflow, the check engine light may illuminate if a PCV valve is stuck open. It is critical to check the PCV valve on a regular basis in order to keep your engine running smoothly.

Pcv Valve

The PCV Valve, or Positive Crankcase Ventilation Valve, is an essential part of a vehicle’s engine. The PCV Valve helps to regulate the pressure inside the crankcase, maintaining the proper amount of vacuum. This vacuum helps to reduce emissions, improve engine performance, and increase fuel efficiency. The PCV valve also helps to reduce oil consumption and oil sludge buildup in the crankcase. It is a relatively small part, but it plays an important role in the overall health of a vehicle’s engine.

A faulty PCV valve in a vehicle can cause rough idling and a buildup of lean air that contributes to the fuel mixture becoming sluggish. It contributes to vehicle emissions by regulating crankcase pressure and preventing unburned fuel vapors from forming. The air intake can only function properly if the PCV valve is properly functioning. The engine may be roughed up and there may be a lean air mix as a result, resulting in increased emissions and a lower fuel economy. The proper operation of a vehicle necessitates the proper functioning of the PCV valve. To do so, one must first shake the valve from the hose or tube. The valve is likely to remain in good working order if a metallic rattling noise is heard. If the valve does not open and close properly when no sound is heard, the valve is most likely no longer operating properly. If you replace a faulty PCV valve, you can reduce rough idling, improve fuel economy, and reduce emissions.

Maintain Your Pcv Valve To Avoid Costly Repairs

The PCV valve, which regulates engine pressure to avoid damaging engine seals, is found on all vehicles. When this valve does not close and open on schedule, it may cause a rough idle, sluggish acceleration, and a slight increase in oil consumption. To ensure that your vehicle runs smoothly, your PCV valve should be replaced at the recommended interval, usually between 20,000 and 50,000 miles. If your vehicle has any of the signs of a faulty PCV valve, it is critical that you have it serviced as soon as possible to avoid further engine damage. This important piece of your vehicle’s engine can be saved money and time by having it checked on a regular basis.